...but - knowing these things (ie. rhetoric below) - would anyone care to attempt to talk ME into choosing silver plated instruments?

- Unless an instrument is quite old, the thickness of the silver bonded over the base metal is seldom more than 1/2000th of an inch thick. I can machine-polish it away in about 1 second or wear it away in a few years of use (hand contact points). Back when silver was cheap, it was sometimes (not always) added to remarkably generous proportions (but not necessarily because the manufacturer cared a whit about "finish durability"). I actually encountered an old H.N. White sousaphone bell that - once I FINALLY managed to buff away all of the (satin finished, fwiw) silver (which was TREMENDOUSLY thick), I discovered that they plated it thick as a work-saving strategy. The base metal brass was rough (never sanded nor buffed), and they obviously plated the rough brass enough to end up with a smooth enough surface, and then (rather than sandblasting the base metal) they sandblasted the silver plating...ok: "clad" silver). I encountered an EARLY satin silver Holton 340 (overly heavy)...same strategy as H.N. White...crazy-thick silver.

- As far as sonic characteristics are concerned (with most all of us agreeing that the shape of the air column overwhelmingly controls the non-human-input aspects of wind instrument sounds), am I to believe that 1/45th (usually less) of the thickness of some non-ferrous sheet metal is going to significantly affect sonic characteristics?

- MORE trombonists than not (who genuinely seem to have compared them) claim that they prefer brass (King 2/3/4/5 and bass) bells over (solid) silver. Curiously (my own observation) King (solid) silver bells sometimes sport an "after-ring" (a non-musical/non-human-controlled sound), vs. the brass ones which (so far, in my experience) never do.

- Without regular polishing (which always takes away part of the thin silver coating - whether abrasively or chemically) my instrument is typically going to look shiny/smeary, gray, or black...correct? If I'm to keep it mirror-shiny, how much time (out of a week/month/year) does this require?

- What's with that sulfurous odor?

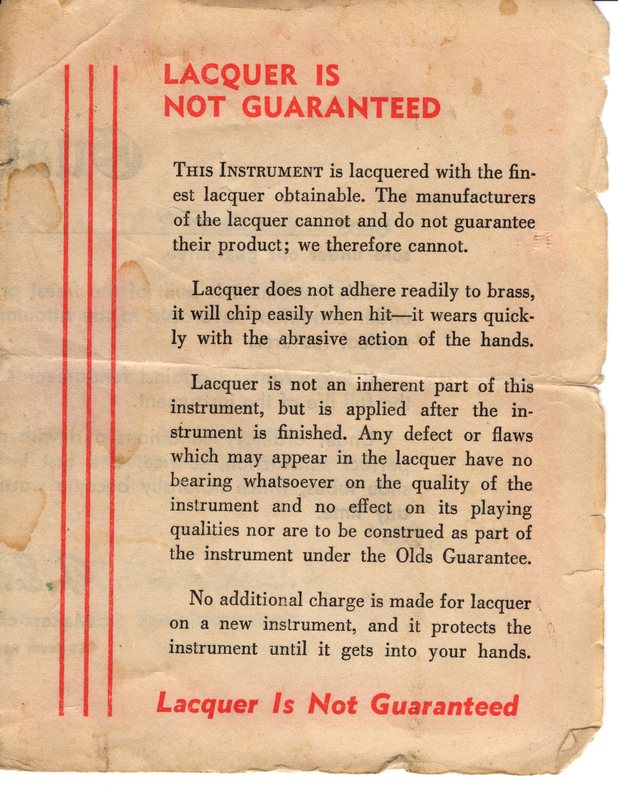

- On a website, Renold Schilke is quoted as claiming that the lacquer on an instrument is typically .007" (remarkably) thick, which defines bell lacquer thickness as .014" total (inside plus outside). It's might be noted that - during his lifetime - the only lacquer-finish instruments that I encountered from his shop were old worn ones - whereby someone seemed to have hand-polished away the remaining silver and lacquered them in some overhaul shop. As this person obviously eschewed lacquering their manufactured instruments, should I automatically trust them as an expert? 3 mil thick trash bags are marketed as durable. I've stripped exoxy lacquer (MANY times), which tends to fall away somewhat intact (as pieces of "sheet"). I've personally never found any that was anywhere near as thick as a 3 mil thick trash bag. Additionally (out of curiosity) I've measured bell thicknesses before and after stripping (both) nitrocellulose and epoxy lacquer...The before/after difference is typically negligible...not much more than silver plating...possibly 1 mil (sometimes up to a 2 mil difference in bell thickness). I've also measured the scraps of stripped epoxy lacquer (remarkably thin), but I can't say that the stripper did not dissolve part of the sheet epoxy lacquer.

- When damaged (most anyone reading this who plays a brass instrument has bumped it against something at least a few times), lacquer-sprayed instruments are much easier to repair (with less harm to the finish) and lacquer can be partially redone, whereas - if someone attempts to partially redo silver plating - it's typically a "ghost"-thickness coating/coloring, whereby to properly redo silver plating requires redoing the entire instrument.

- WOULD I GO AHEAD AND BUY A SILVER PLATED INSTRUMENT, WERE IT THAT IT PLAYED CRAZY-WELL AND IT WAS SOME ELUSIVE MAKE/MODEL (AND AT SOME AMAZING LOW PRICE) THAT I'D BEEN SEEKING FOR YEARS...??

...You bet I would.

Finally, Mr. Donn always likes to offer counterpoints, which make me smile.